Always prepared for bumps in the road

We would like to present three actual cases where we managed to attain the desired level of manufacturability. We could claim that all three projects progressed smoothly from A to B without any surprises whatsoever, but that would of course be a lie. You really can’t tell in the very beginning where a project will end up. You can set all the relevant objectives and write, on some kind of level, a spec. Nevertheless, obstacles will surface, no matter how well you have prepared. Then again, this is of course what makes projects like these so captivating! Learning together – and from each other, overcoming obstacles and solving the enigma of manufacturability. We are proud of our collaboration with Findmy, Airmont and Surfact – and what we have achieved together!

Our humble beginnings of working structurally towards automation – together with the customer!

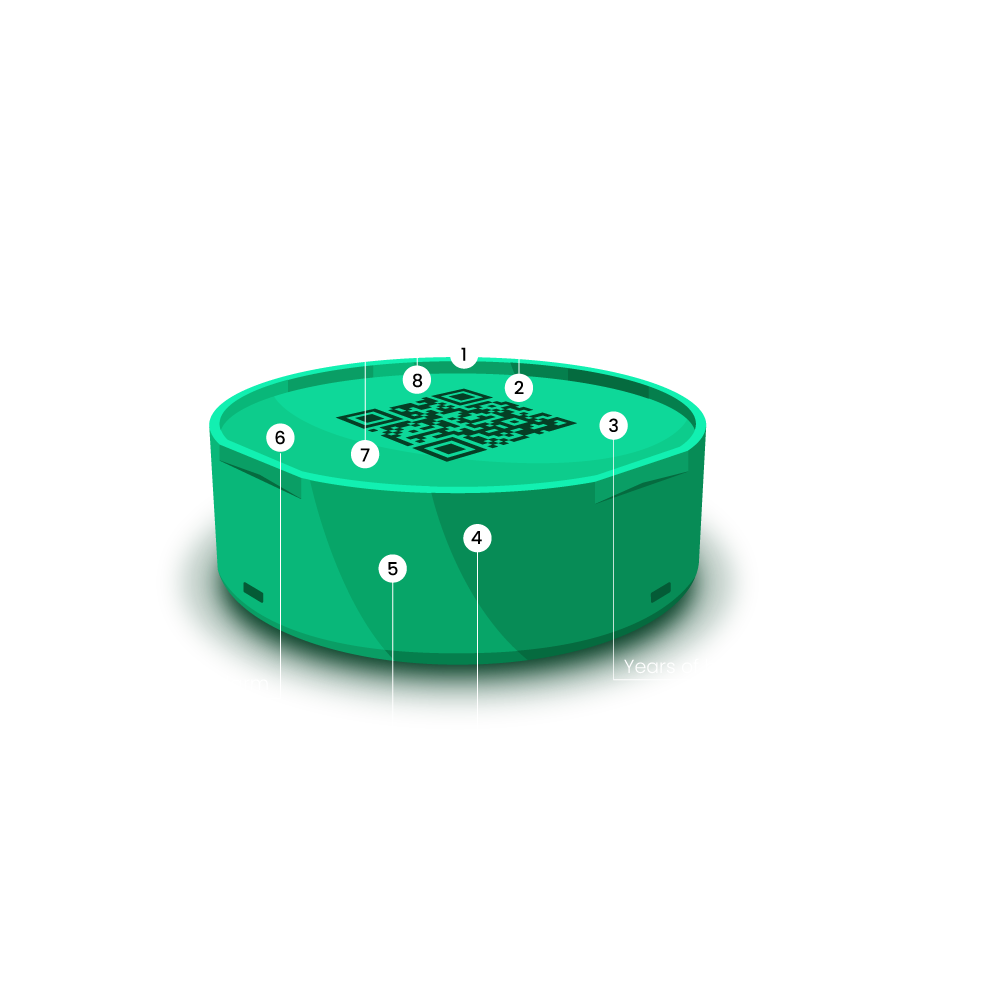

Designing and manufacturing an animal tracking device

should be pretty straight forward, wouldn’t you think?

Nope, the animals are surprisingly capable of causing

significant stress to the device. Also, the device will

be worn by both frail lambs and sturdy bulls. Hence,

most of the focus was directed towards protecting the

electronics – but at the lowest possible cost. The final solution included separate chambers for battery and electronics, where PCBA is potted. The lid is fixed with

ultrasonic welding and all marking is done with laser.

Final test is done in parallel with potting process. AXXE

will always be grateful Findmy for choosing to work with

us on this project!

IoT devices are popping up everywhere, but this one is meant for an unlikely place...

The Chimney Sensor is attached to the – yes, chimney –

and provides safety data related to the use of connected

fireplaces. The operating environment is, to put it mildly,

extreme harsh, with potentially minus 25 degrees

Celsius outside the chimney, while (pluss!) 600 degrees

Celsius on the inside. Then add the exposure of sunlight,

humidity, wind, rain and snow. It must be easy to install

and have a battery life of at least 10 years. We managed

to reduce manual operations to an absolute minimum

by making use of the “hamburger principle”, selective

soldering and snap-fit solutions. As a final touch, the

potting material serves two purposes: Protecting the

electronics AND as a lid.

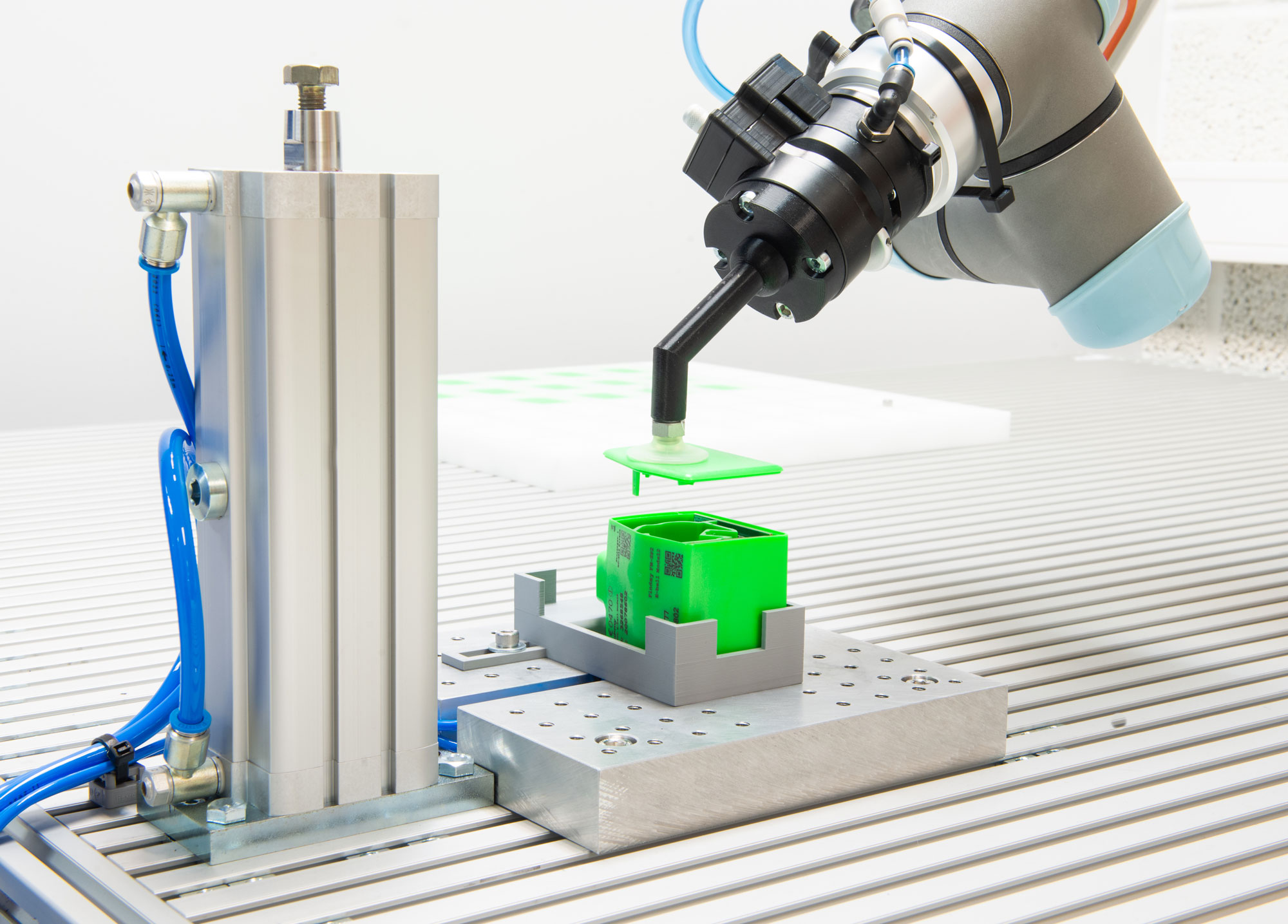

Our first project where full automation was a prerequisite throughout the design process.

This groundbreaking, sustainable asset tracking device is exciting for a number of reasons, but at AXXE we are especially impressed with the mindset of Surfact during the design process: All aspects of the final product, such as manufacturability, features, looks, cost, quality and sustainability, were continuously evaluated on equal terms. Cudos! The highlights of the design process were mechanical solutions that enabled efficient change of batteries along with full recyclability – and at the same time providing stable support for all electronics. Through team-work, patience and innovation, we now have a product that meets the initial spec – with no manual operations!